1. Preparation before installation

Before installation, you need to prepare some necessary tools and materials, including: Brazilian Double Cam Oval Brass Lock Cylinder and its matching key. Screwdrivers, wrenches, pliers and other tools. Lock cylinder lubricant. Measuring tools, such as tape measures and vernier calipers, to ensure the lock cylinder matches the door lock hole.

2. Installation steps

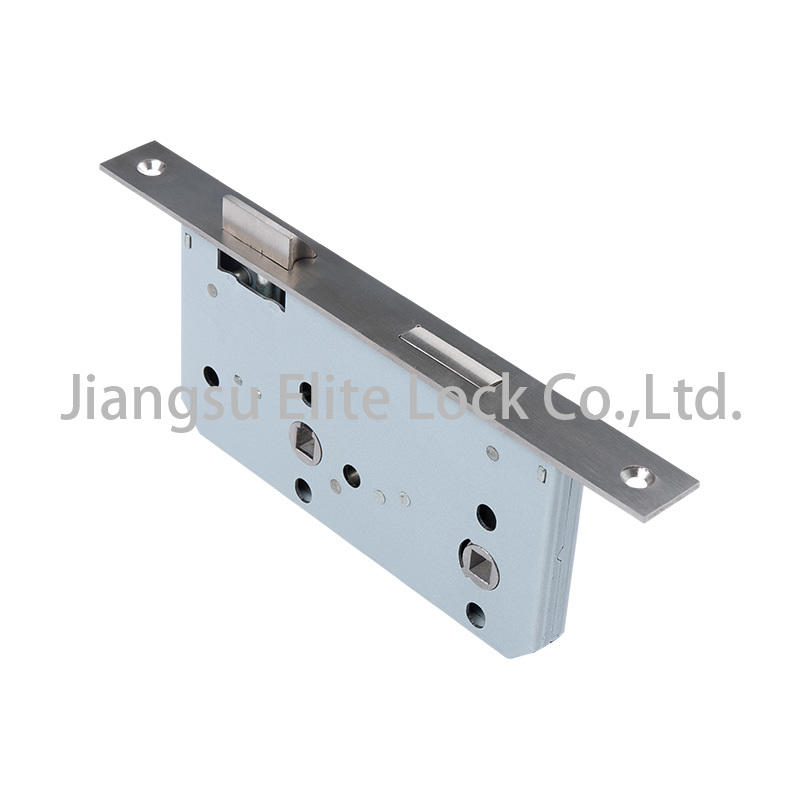

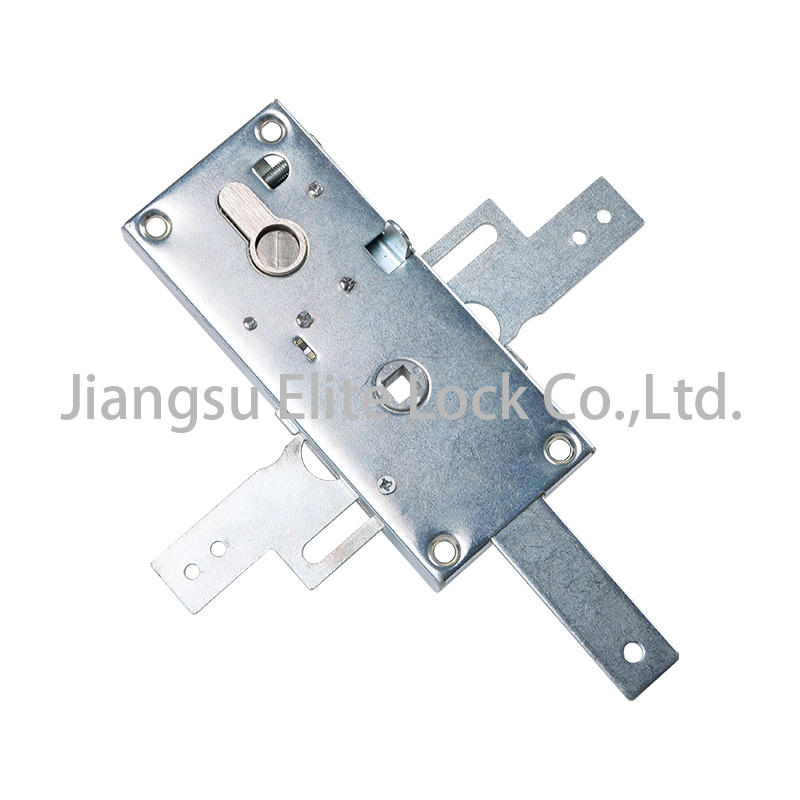

Measurement and fitting: First, use a measuring tool to measure the size of the original lock cylinder to ensure that the new lock cylinder matches the door lock hole. If the dimensions do not match, the door lock hole may need to be reamed or adjusted.

Remove the old lock cylinder: Use tools such as a screwdriver or wrench to remove the original lock cylinder from the door lock. Be careful during disassembly to avoid damaging other parts of the door lock.

Install the new lock cylinder: Place the new Brazilian Double Cam Oval Brass Lock Cylinder into the door lock hole, making sure the lock cylinder is oriented correctly. Use tools such as a wrench to fix the lock core in the door lock, ensuring that the lock core is firm and does not shake.

Testing and adjustment: After installation is completed, use the matching key to test the opening and locking functions of the lock cylinder. If it jams or cannot be opened smoothly, the lock cylinder may need to be fine-tuned to ensure it works properly.

3. Maintenance precautions

Regular cleaning: Use a clean cloth or paper towel to wipe the surface of the lock cylinder regularly to remove dust and dirt. Avoid using cleaners containing chemical ingredients to avoid corrosion of the lock core.

Lubrication and maintenance: Good lubrication and maintenance can reduce friction, reduce wear, extend the service life of equipment, and improve work efficiency. For the lock cylinder, proper lubrication can reduce resistance when the key is inserted and removed, making the operation smoother, and also helps prevent rust and corrosion. For precision parts such as lock cores, special lock core lubricants or light engine oil should be selected. Avoid using heavy grease or unsuitable lubricants to avoid clogging the lock cylinder or affecting the use effect. Before performing lubrication and maintenance, you first need to wipe the surface of the lock cylinder with a clean cloth or paper towel to remove dust and dirt. Make sure the surface of the lock cylinder is clean and free of impurities to avoid affecting the lubrication effect. Use a tool such as a dropper or cotton swab to apply an appropriate amount of lubricant to the sliding part of the lock cylinder and inside the keyhole. Be careful not to apply too much to avoid spilling or dripping onto other areas. After applying lubricant, insert and remove the key several times to test whether the lock cylinder slides smoothly. If necessary, the amount of lubricating oil can be adjusted appropriately.

Avoid impact: Avoid hitting the lock cylinder with heavy objects or twisting the key forcefully to avoid damage to the lock cylinder.

Pay attention to key storage: Keep the key of the lock cylinder properly to avoid loss or theft. If the key is lost, the lock cylinder should be replaced in time to ensure safety.

Regular inspection: Regularly check the working status of the lock cylinder. If any abnormality or failure is found, repair or replace it in time.

4. Troubleshooting and maintenance

During use, if there is a problem such as the lock cylinder being unable to open or stuck, you can follow the following steps for troubleshooting and repair:

Check the key: First check whether the key matches and whether it is damaged or deformed. If there is a problem, replace the key promptly.

Clean the lock cylinder: Use a cleaning cloth to wipe the surface of the lock cylinder to remove dust and dirt.

Lubricate the lock cylinder: If the lock cylinder is still stuck, you can use an appropriate amount of lubricating oil to lubricate it.

Check the installation: If none of the above methods work, you may need to check the installation of the lock cylinder to make sure it is secure and oriented correctly.

Replace the lock cylinder: If the lock cylinder is seriously damaged or cannot be repaired, replace it with a new lock cylinder in time.

.png?imageView2/2/format/jp2)

English

English Español

Español русский

русский