1. Daily maintenance

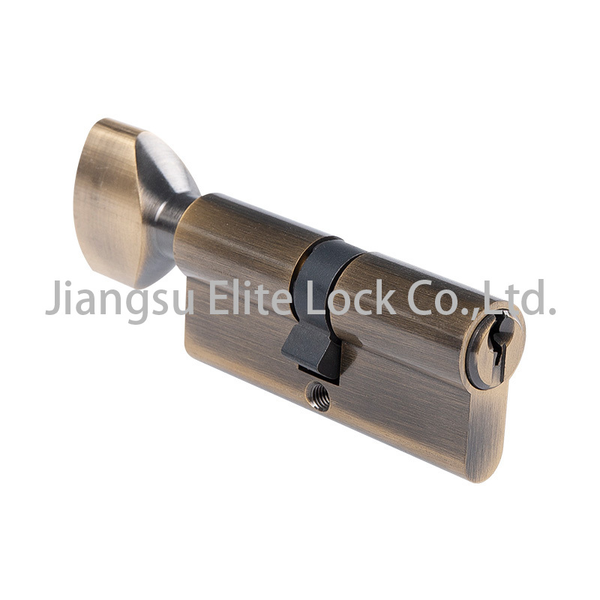

Routine maintenance is the basis for ensuring the stable operation of the European single-handle brass lock cylinder. In daily life, you should pay attention to the following points:

Regular cleaning: Regularly wipe the surface of the lock cylinder with a clean soft cloth to remove dust, stains and fingerprints that may be attached. It should be noted that cleaning agents containing chemical ingredients should be avoided when cleaning to prevent damage to the brass material.

Avoid excessive force: Excessive force may damage the precision parts inside the lock cylinder, causing the lock cylinder to malfunction. Therefore, when turning the handle or inserting the key, do so gently and evenly.

Pay attention to waterproofing and moisture-proofing: There are many precision parts inside the European-style single-handle brass lock cylinder. Prolonged exposure to water or humid environment may cause rust or corrosion. Therefore, when installing and using the lock cylinder, we should choose a dry and ventilated location and avoid being exposed to rain or humid air for a long time.

We should also regularly check whether the fixing screws of the lock cylinder are loose. If the screws are found to be loose, they should be tightened with appropriate tools in time to avoid the lock cylinder being displaced or damaged due to loose screws. Through these daily maintenance measures, we can ensure that the European-style single-handle brass lock core is in the best working condition, extend its service life, and provide safe and reliable protection for our lives and work.

2. Regular maintenance

In addition to routine maintenance, European-style single-handle brass lock cylinders also require regular in-depth maintenance to extend their service life.

Lubrication and maintenance: Every once in a while (such as every quarter or every six months), special lock core lubricating oil can be used to lubricate and maintain the lock core. Drop the lubricating oil into the lock cylinder hole and gently turn the key several times to distribute the lubricating oil evenly and ensure that the lock cylinder rotates smoothly.

Fastening screws: Regularly check whether the lock core fixing screws are loose. If they are loose, tighten them in time. Avoid loose screws that may cause the lock cylinder to shift or be damaged.

Check parts: Regularly check whether the parts inside the lock cylinder are intact. If there are any damaged or severely worn parts, they should be replaced in time. When replacing parts, specifications and models that match the original parts should be selected to ensure the normal operation of the lock cylinder.

3. Handling special situations

In some special cases, European style single handle brass lock cylinders may require special treatment.

Dealing with rust: If the lock core is rusted, you can use a special rust remover to deal with it. However, it should be noted that rust remover may have a certain impact on brass materials, so a small area test should be carried out in an inconspicuous location before use.

Dealing with external force damage: If the lock core is damaged by external force (such as impact, lock prying, etc.), stop using it immediately and contact a professional for maintenance or replacement. Never force use of a damaged lock cylinder to avoid greater losses or safety hazards.

4. Precautions for use

When using a European-style single-handle brass lock cylinder, you should also pay attention to the following points:

Avoid using improper keys: Do not use a key that does not match the lock cylinder to try to open the lock to avoid damaging the internal structure of the lock cylinder.

Pay attention to keeping spare keys: In order to prevent unexpected situations from being unable to open the lock, it is recommended to keep spare keys in a safe and reliable place.

Regularly replace the lock cylinder: To ensure safety performance, it is recommended to replace the lock cylinder regularly (such as every two to three years). When replacing, you should choose lock cylinder products of regular brands and reliable quality.

.png?imageView2/2/format/jp2)

English

English Español

Español русский

русский