1.Uncompromising Materials: The Foundation of Lock Safety

1.1 Strict Selection of Corrosion-Resistant, High-Strength Metals

China lock factories prioritize the use of premium-grade raw materials as the foundation for secure and durable locks. Only metals that pass rigorous corrosion resistance and tensile strength tests are selected. This ensures long-term reliability under various environmental and usage conditions.

1.2 Supplier Vetting and Compliance with Industry Standards

Raw material suppliers undergo a strict evaluation process to ensure that all incoming materials meet national and international safety standards. Certificates of compliance and sample-based inspections help guarantee that only the most consistent and reliable materials enter the manufacturing pipeline.

1.3 Material Traceability and Batch-Level Quality Assurance

Each batch of raw materials is tagged and recorded in the factory’s traceability system, allowing any quality deviation to be traced back to its origin. This closed-loop tracking ensures full accountability and rapid correction in case of anomalies, reinforcing the factory’s commitment to quality at the source.

2.Precision Manufacturing Meets High-Security Engineering

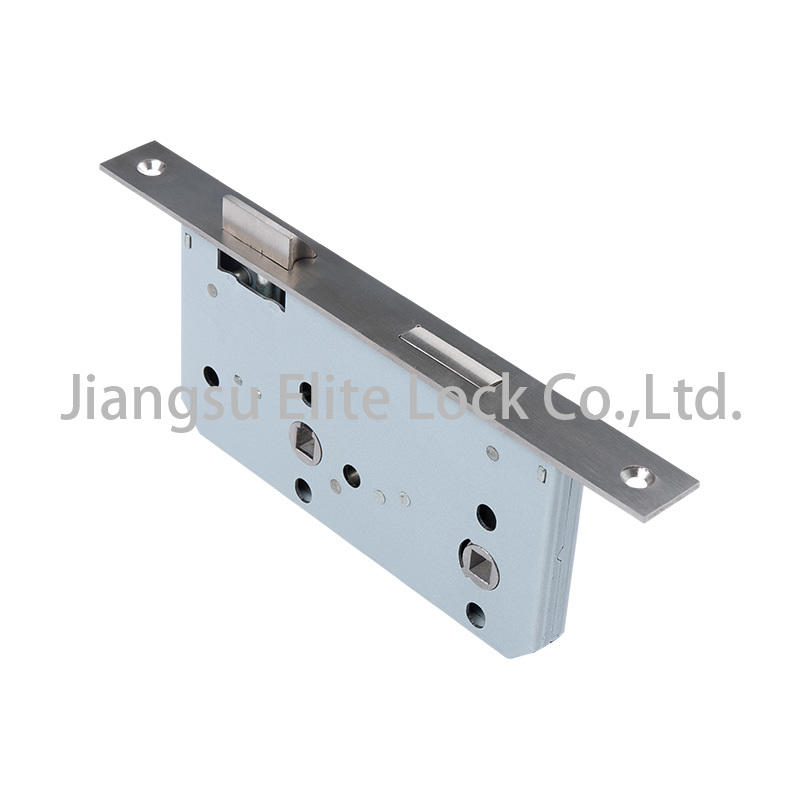

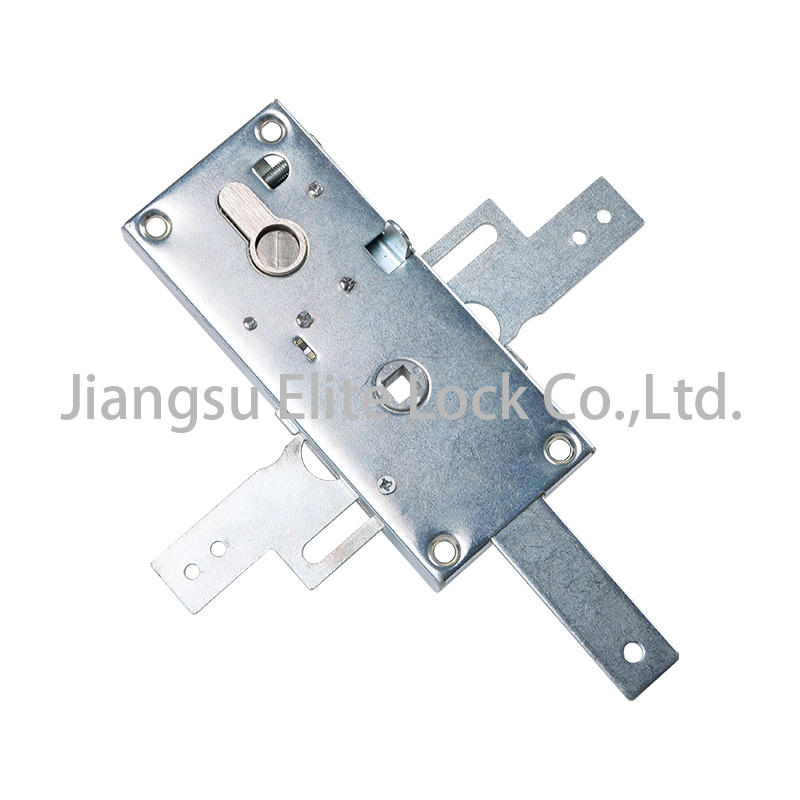

2.1 High-Precision Machining for Seamless Fit and Function

Using advanced CNC machining and robotic tooling, every lock component is crafted to tight tolerances. This precision ensures a perfect fit between internal parts, leading to smoother operation, higher resistance to tampering, and minimal wear over time.

2.2 Multi-Level Functional Integration During Assembly

China lock factories implement layered quality checkpoints during the assembly process. From cylinder integration to spring calibration, each subcomponent is tested and verified before it is embedded into the final structure—ensuring operational consistency and mechanical integrity.

2.3 Built-in Security Features Validated Through In-Process Testing

Security-critical features like anti-pick pins, anti-drill plates, and reinforced latch mechanisms are tested during assembly. These proactive assessments ensure that every lock maintains optimal protective capabilities before final inspection, not just post-production.

3.Full-Cycle Quality Control and Continuous Innovation Drive Trust

3.1 Comprehensive Product Testing Simulates Real-World Abuse

Final-stage quality control includes endurance testing (e.g., 100,000+ cycle testing), impact resistance simulations, and water ingress assessments to ensure locks perform flawlessly in both daily use and hostile conditions. This testing emulates years of wear within hours.

3.2 Full-Process Quality Management with Zero-Tolerance Policies

Every stage—from sourcing to packaging—is embedded in a strict quality management framework. Non-conforming components are immediately removed from the production line, while continuous feedback loops between departments prevent quality lapses across batches.

3.3 Ongoing R&D Investments Fuel Product Advancement

To meet evolving safety expectations, China lock factories are actively investing in R&D. From smart locking mechanisms to eco-friendly material integration, continuous innovation ensures their products stay ahead of market trends while enhancing security, efficiency, and environmental responsibility.

.png?imageView2/2/format/jp2)

English

English Español

Español русский

русский